Motiv Ring, the activity, sleep, and heart rate device you want to wear

Founded Motiv in 2013 along with three other talented individuals and successfully delivered the Motiv Ring to the market in September of 2017. I am responsible for driving the diminutive form factor, helping with raising funds, sourcing innovative components, and driving the technology direction of the company.

The Early Days

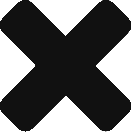

I sold my truck for $11k, cashed out my 401K, and walked to work for a several months to pay for prototypes and patents. This is our first development board that included all of the components required for the first ring design. No curved cell batteries existed so our first proto was the flat black stick on the left.

Make everything ourselves

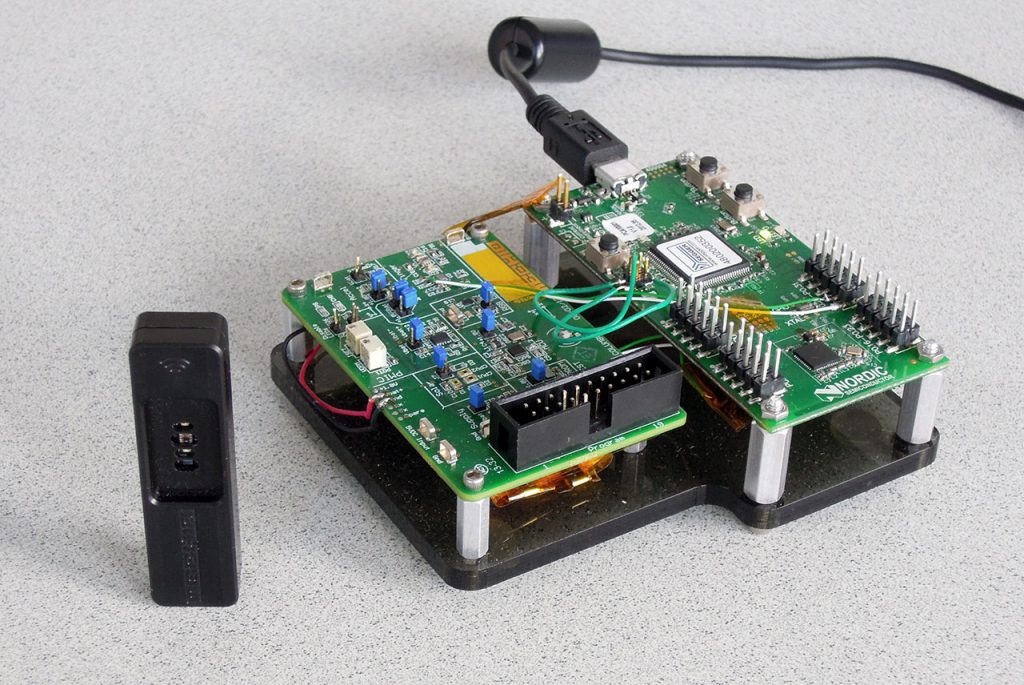

We designed the flexible circuit board and algorithms from scratch – these were the days before off-the-shelf PPG and sleep libraries were available to ultra low power wearables. Many of the components were some of the first WLCSP offerings available on the market.

Developed tools to program, test, and verify

Programming small flex circuits is difficult. I designed several different types of programming fixtures before eventually narrowing down to a design that allowed us to easily debug and test the flex circuits without soldering wires to test points. Production fixtures followed and we refined the design to ease the programming ad testing time on the line significantly.

Machined and assembled the first protos

Some of the first rings we made in late 2014 had a very different design than that of the shipping product – an outer housing with the electronics inside and over molded. These protos, shown before molding, had flat cells that we bent causing wrinkles (an early learning that proved challenging to resolve). This particular design also had solar charging that could generate enough power in direct sunlight to run the device without charging

The curved battery problem

Getting a curved cell manufactured was not an easy task. We went through several vendors before we came across one company that was finally able to make a wrinkle-free cell to our specifications. Lots of effort went into the electrode design, materials, and construction to get a high energy density in such a small space.

Developed novel over molding techniques

This is our first over molded ring – we used a novel UV curing process with a clear mold design. The battery was charged with a clip-on connector and spring pins. The early firmware was very power intensive and gave us just enough time to give demos for about 1/2 hour. Luckily we were able to bring on some world class firmware folks that drove that number up to 3 days.

The final ring design had two CPUs (one for Bluetooth/firmware management and the other for our sensor management/algorithms. We had a very talented team that created innovative ways to maintain a three day battery life while operating multiple sensors, machine learning algorithms, data consolidation/compression processes, and BLE communications protocols.