Manufactured accessories for the motion picture and camera industry. Operating for over 10 years, the products ranged from CNC plates and cages up to electronic focus and remote control systems. I designed the products, generated the CAD models, generated drawings, CAM profiles, designed fixtures, setup mills, designed circuit boards, and coded the firmware. It was a very fulfilling experience (albeit labor intensive) .

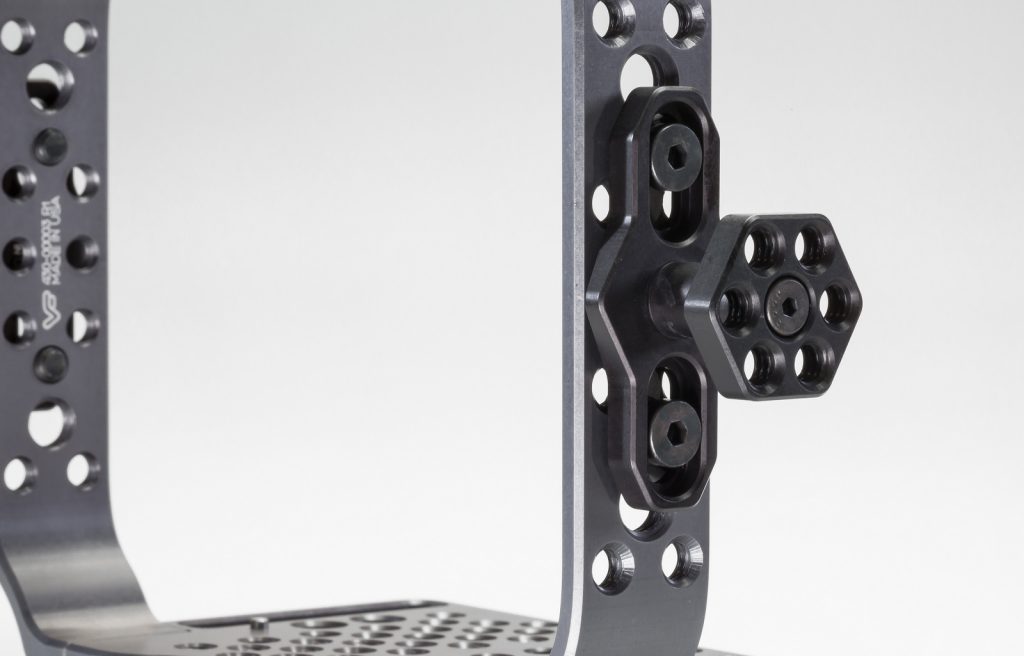

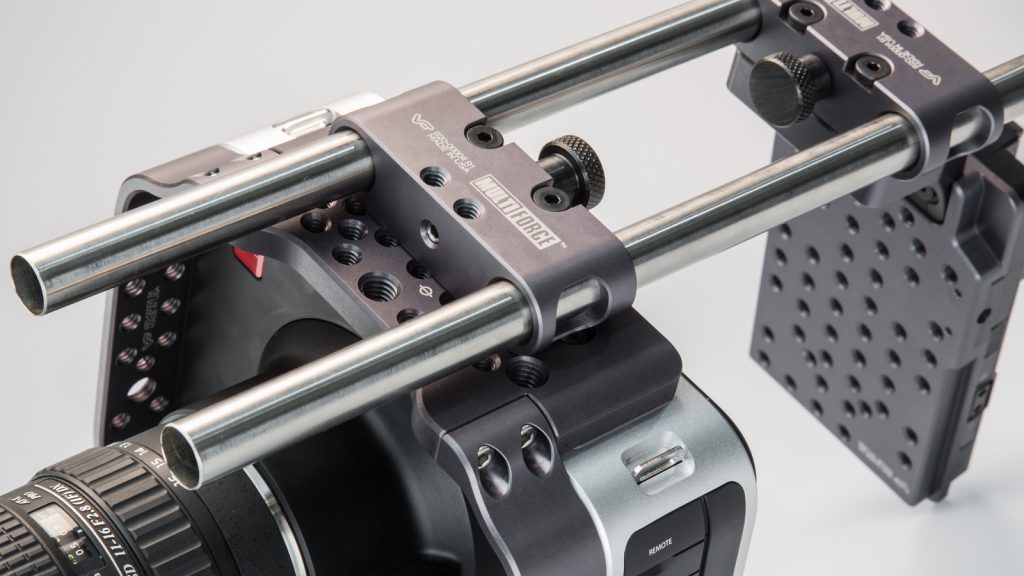

Blackmagic Cinema Camera Accessories

We developed this line of accessories to allow customers to mount their professional cinema accessories on the BMCC. The design is streamlined and meant to blend into the camera. There were several follow on products, including a 15mm multiforce rod bracket and battery plates. The multiforce had an internal ball bearing mechanism that amplified the force exerted by the thumbscrew allowing quick and easy clamping of standard rods to the camera.

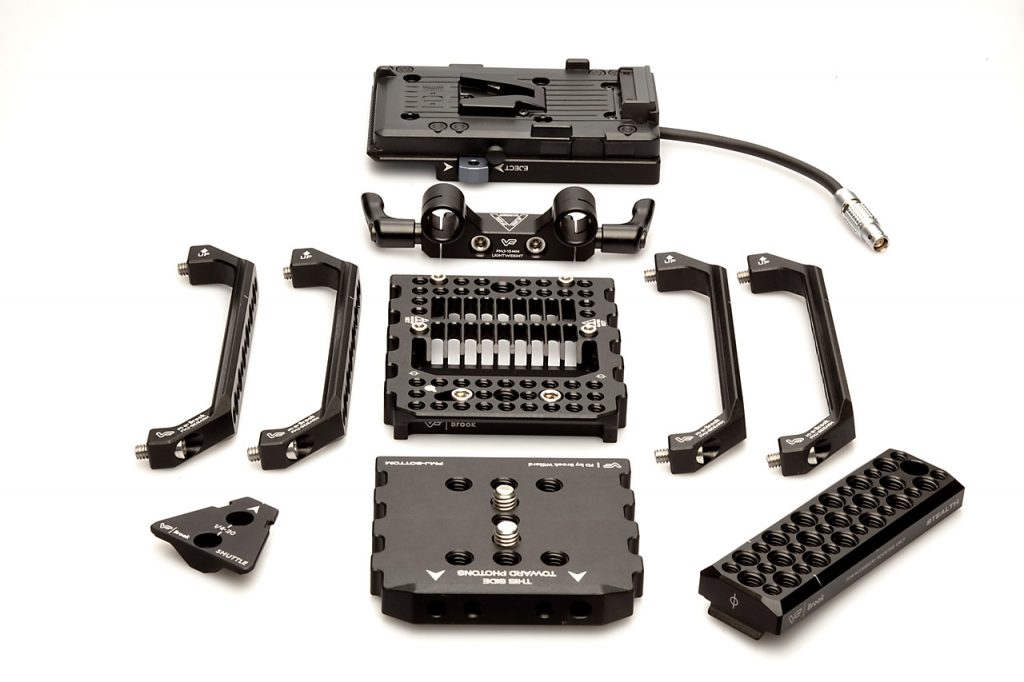

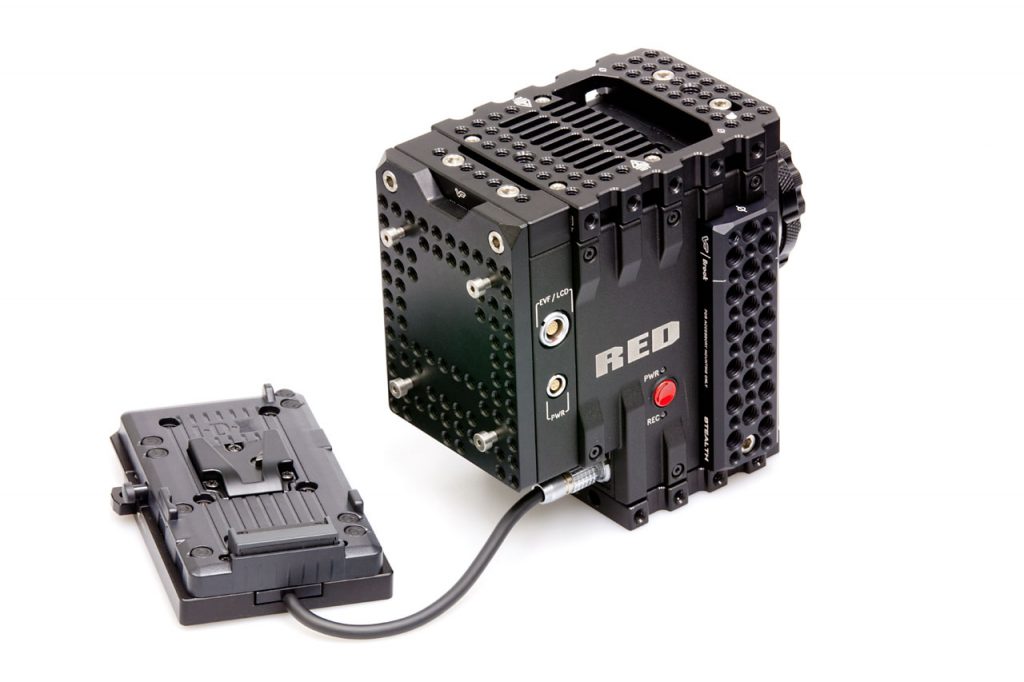

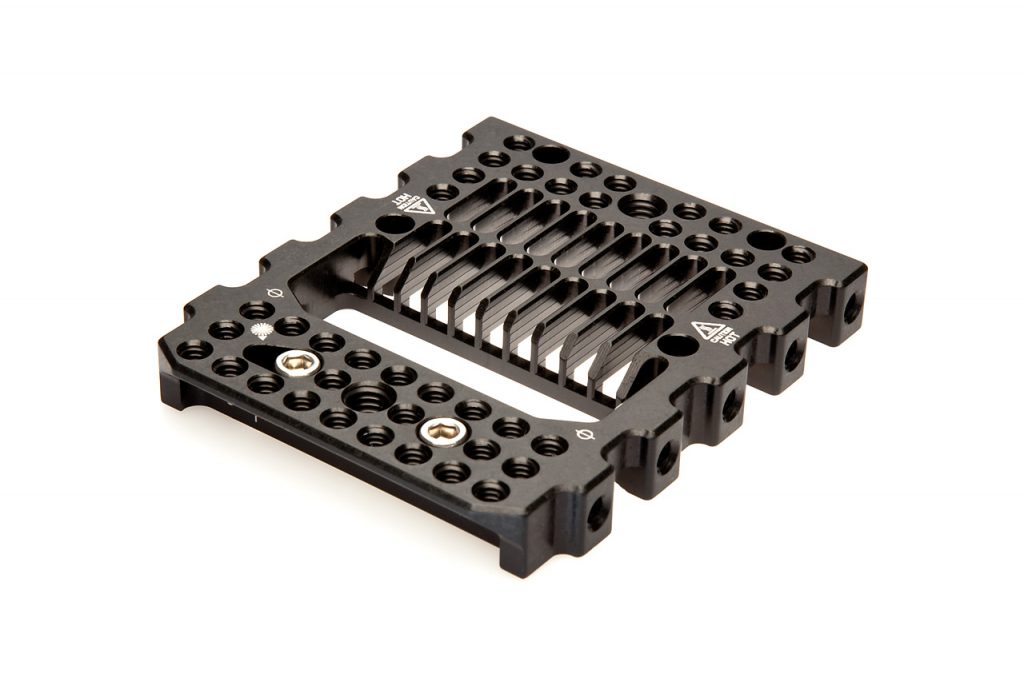

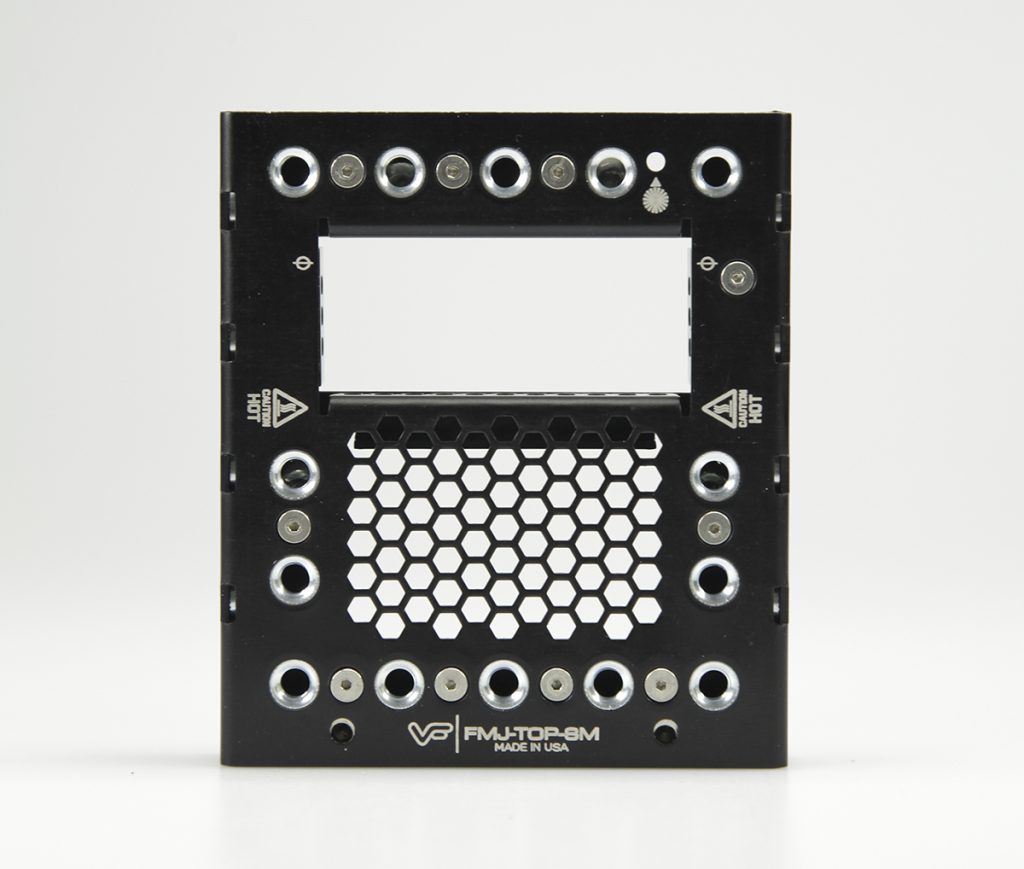

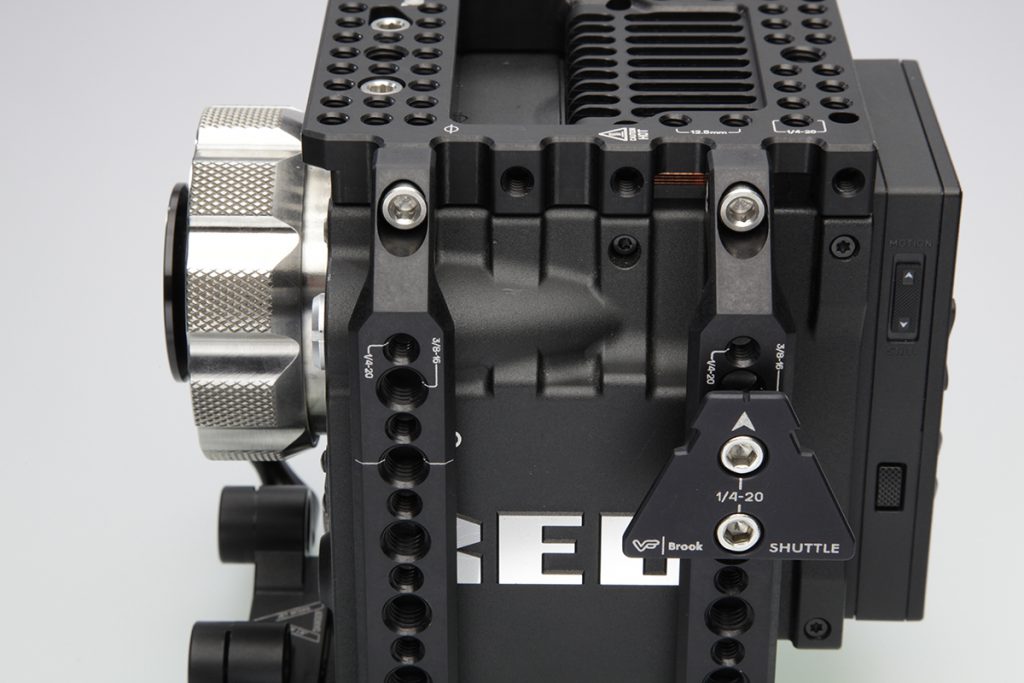

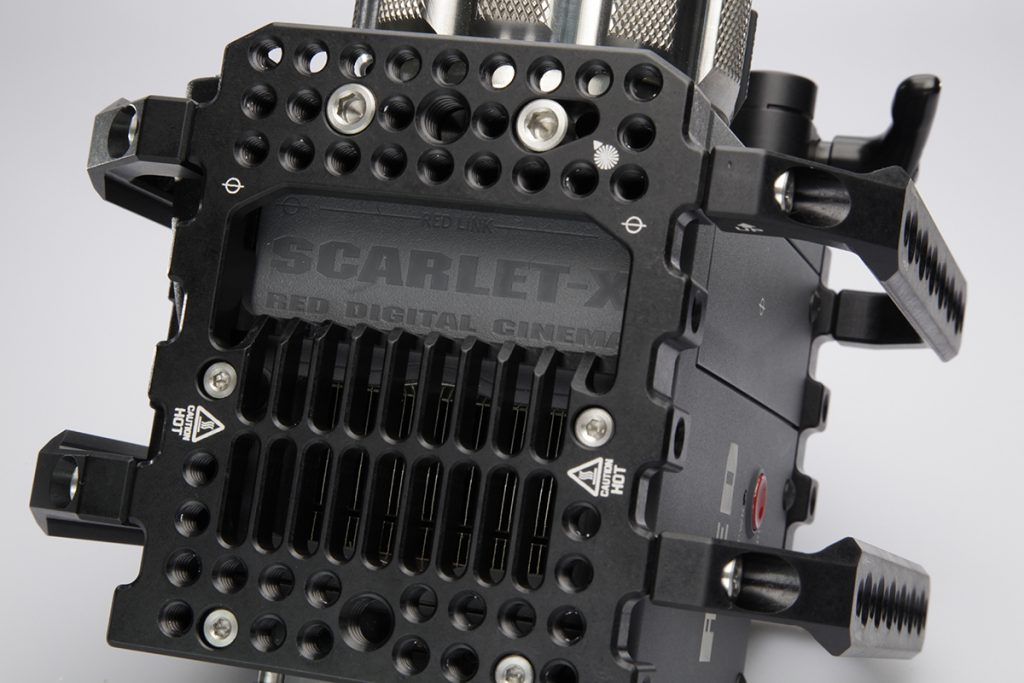

Red Digital Cinema Camera Accessories

The accessories for the Epic and Scarlet were fairly revolutionary. The design of the side arms was based on standard military picatinny rails that allowed users to easily add and remove accessories. The entire FMJ line of accessories gave filmmakers a robust platform to mount their monitors, cinetapes, and other professional accessories. in addition to using standard film camera batteries such as IDX and Anton Bauer.

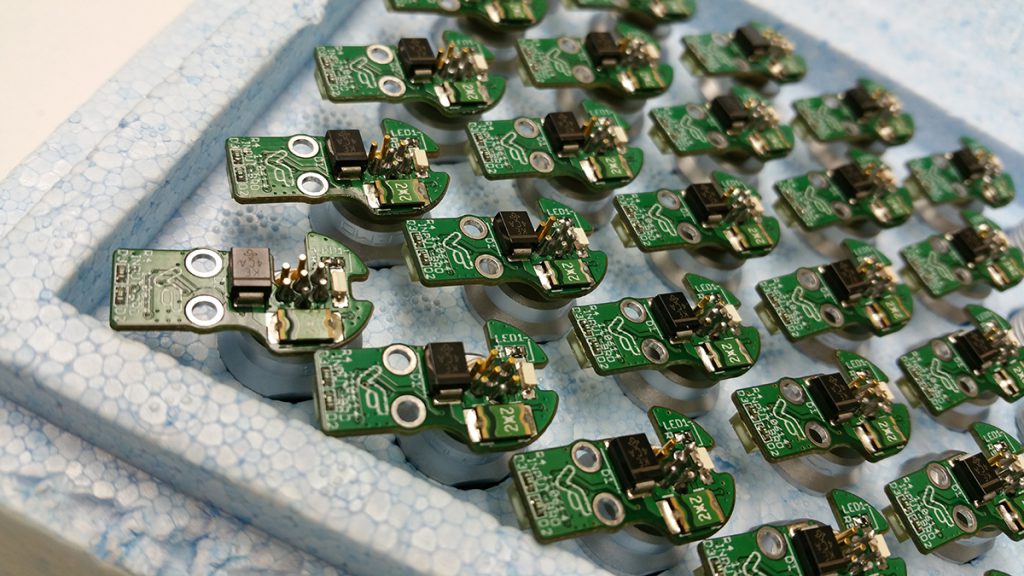

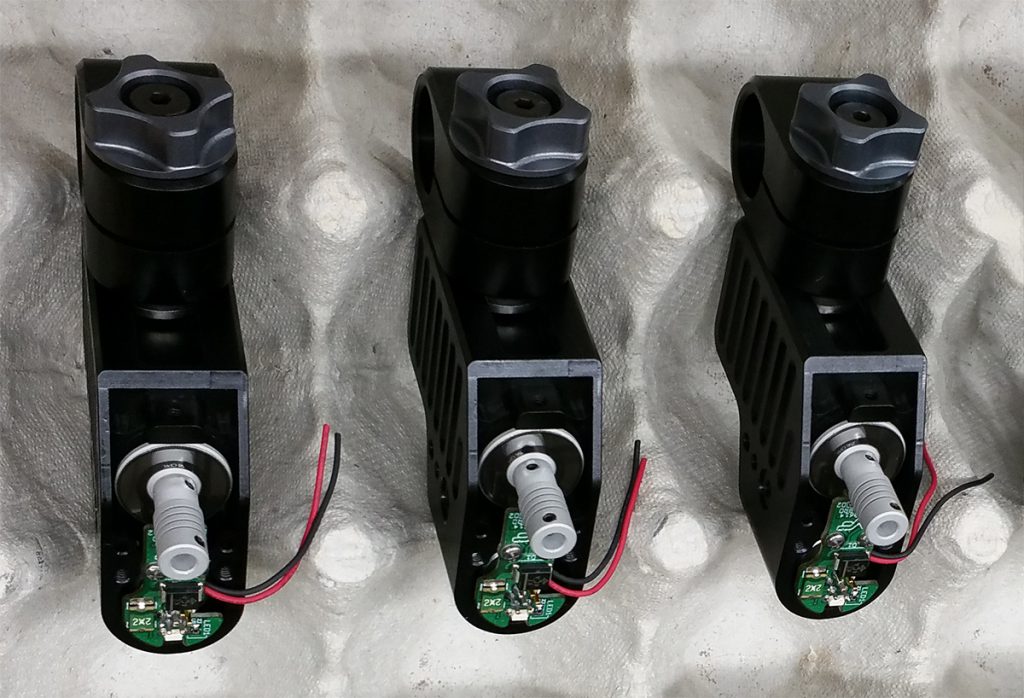

Inclino Wireless Remote Follow Focus

The inclino follow focus system allowed users to remotely control focus on their cinema lenses. This system comprised of small focus unit with a custom brushless motor, encoder and worm gear drive. The receiver contained a DCDC convertor as well as a 3 axis motion control system that interfaced over a FHSS radio to the hand controller. The controller consisted of a damped control know with removable marking rings, two optical input devices and a display.

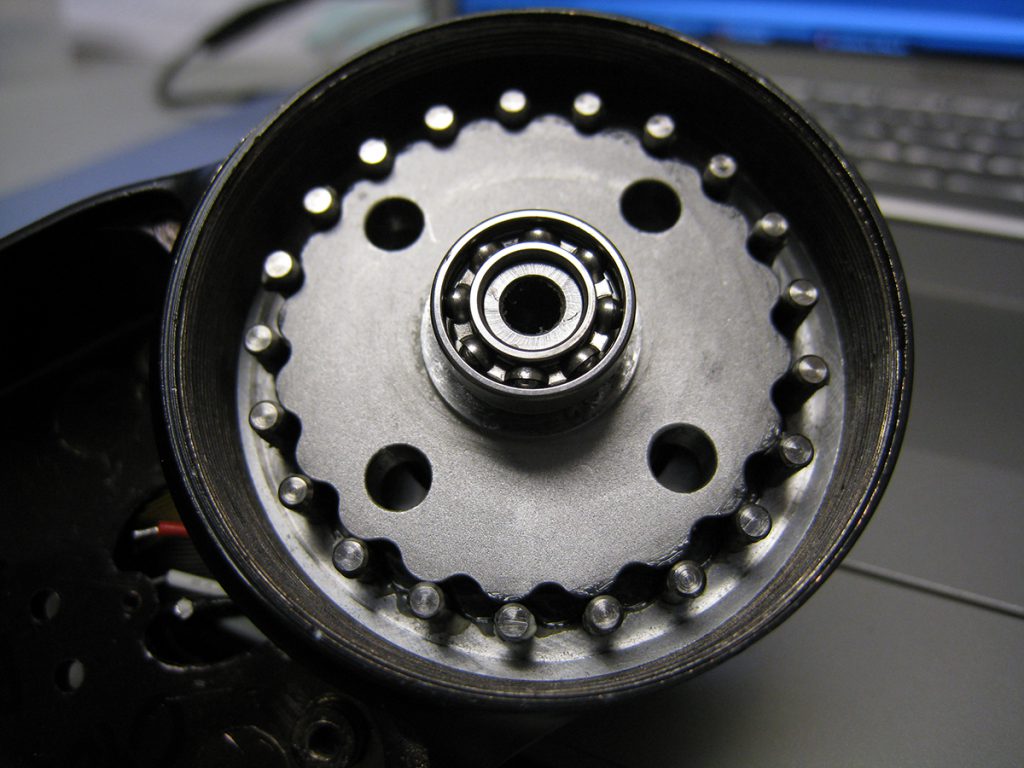

Research – Cycloid and Spur Gearbox designs

These are several projects to explore alternative transmissions for our follow focus motors. I designed a compact spur gear drive train as well as a cycloid and ball-cycloid transmission. All of the cycloid designs allowed for in-house manufacturing on our mills and lathes with no need for a gear cutting machine.

GoPro Camera Modifications – NOVO Camera

The Novo cameras were based on modified GoPros. I reverse engineered the mechanical components and designed a center placed lens mount to accept C-Mount lenses. Additionally, I reverse engineered the communications protocols on the serial lines for the on board MCU and developed a PCBA that could inject commands upon pressing a button. This allowed me to add functionality such as shutter speed and ISO control that is not standard on the commercially available GoPro cameras.

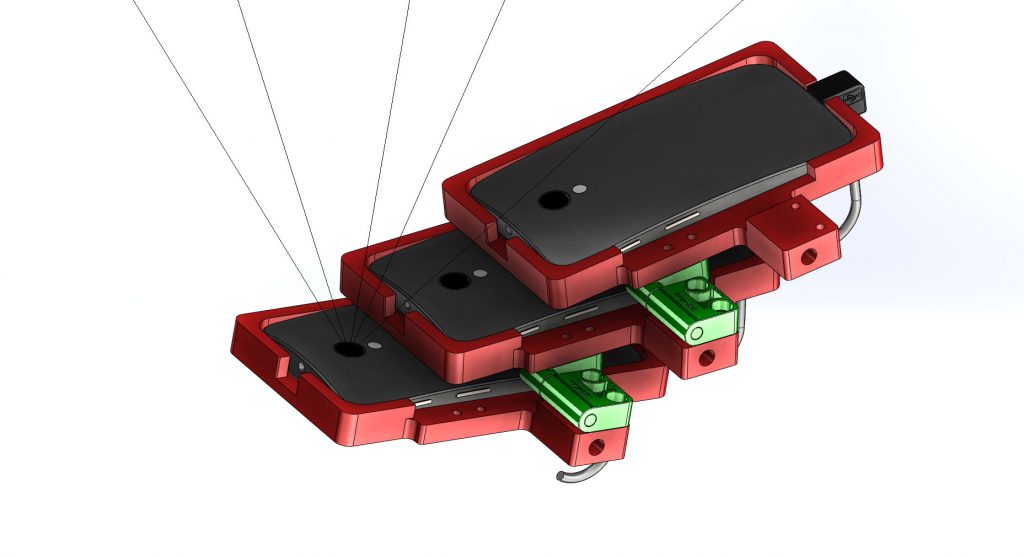

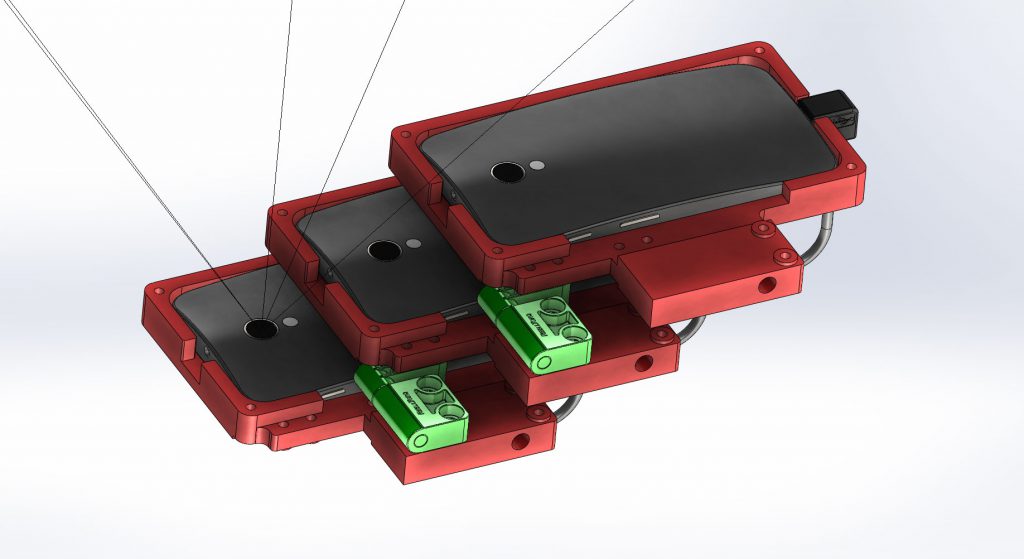

Poseable Bullet Time Cell Phone Array – Completed in under 3 weeks

This was a project for the SanDisks booth at the mobile world congress. We were tasked with making an array of 120 cell phones simultaneously take a picture. I had to design a keyboard emulator that could accept a GPIO signal thru the USB port on the phone as then develop a script that would grab all the frames off the cameras and sequence into a movie similar to the bullet time shot in the Matrix movies.